Share to

Grape juice production line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- DESCRIPTION

-

Shandong Vodasco Intelligent Technology Co., Ltd. integrates advanced European and American technologies and combines the investment characteristics of mainland China to form an incisive processing solution for grape processing production lines. It can design customer projects on a case-by-case basis according to the company's investment status and production reality, and hand over a truly turnkey project to the customer. We are committed to developing innovative equipment to improve overall operating efficiency and greatly reduce capital investment.

The design of the entire grape processing plant adheres to our company's long-term experience in building juice/concentrated juice factories, absorbs mature raw fruit pre-treatment methods and juice/concentrated juice post-processing technology from countries and regions such as Italy and Taiwan, and combines processing equipment with process methods to provide a professional grape concentrated juice production solution that complies with scientific beverage industry production processes; Excellent equipment manufacturing quality and engineering installation quality ensure that the entire system is well designed, compact in structure, beautiful in appearance, and reasonably arranged.1. Technical features

raw material

Fresh grapes

Finished Product

Concentrated or clear juice

Capacity

10 tons/day-1500 tons/day

Juice yield

62.5%

Initial sugar content

15-16Brix

Terminal sugar content

58-60Brix

Fresh grapes: juice=8:1

Concentrated pre-juice: Concentrated juice=5:1Finished product packaging

Aseptic big bag/tin/glass bottle/PET bottle

Yield

Customized according to customer needs

2. System Features

* Processing capacity: 10 tons/day to 1500 tons/day for industrial production, and less than 10 tons/day for experimental research and development.

* Both can process fresh berries with similar characteristics.

* Both use airbag juicers and inert gases to increase the juice extraction rate and guarantee the quality and color of the juice to a greater extent.

* The entire production process is controlled by PLC, and the one-button operating system greatly optimizes the rational allocation of human resources.

* The electrical components of the equipment are internationally renowned brands (such as Germany's SIEMENS, Italy's ESA, etc.), which improves the quality and service life of the equipment.

* The production of grape concentrated juice uses a low-temperature vacuum three-effect evaporator, which greatly reduces energy consumption and saves more than 30% of energy; at the same time, the low temperature state retains the flavor substances and nutrients of the grapes to the maximum extent, so that the tannin substances in the grapes are optimized to the maximum extent. For the cooling water of the evaporator, the design adopts an external water tank circulation supply to reduce the waste of cooling water.

* The original juice batching center is equipped with an enzymatic hydrolysis and degumming system, which can pre-treat the original juice with enzymatic degumming according to the product process requirements, and enhance the adaptability of the product to the later processing.

* The combination of multi-stage original juice separation device and temperature control can maximize the interception of flocculation components in the original juice according to the process line, which is conducive to the stability of the juice in the later stage.

* The entire process design and pipeline connection layout take into account the retention of the original natural aromatic components of grape concentrated juice. The entire cooling and heating process and material transmission are completed in a short time and short distance, which effectively prevents the loss of flavor substances produced by thermal sensitive reactions; at the same time, it also reduces the quality damage caused by the oxidation reaction of grape juice under high temperature; and is equipped with an aromatic substance recovery system to perfectly reproduce the original flavor of grape juice.

* Tubular sterilization and aseptic filling ensure the sterility of the product.

* CIP automatic cleaning function: Through the reasonable design of the pipelines and equipment of this production line, the CIP cleaning station can be divided into sections and independently complete the CIP cleaning operation to ensure the safety and sanitation of the production line.

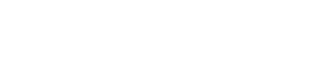

* The material contact parts of the system are all made of 304 stainless steel, which fully meets the requirements of food hygiene and safety.3. Process flow

Grape juice production line

Still deciding? Get samples first, Contact US !

Tag list

Complete set of technical solutions

and service providers for the fluid industry

Precision welding

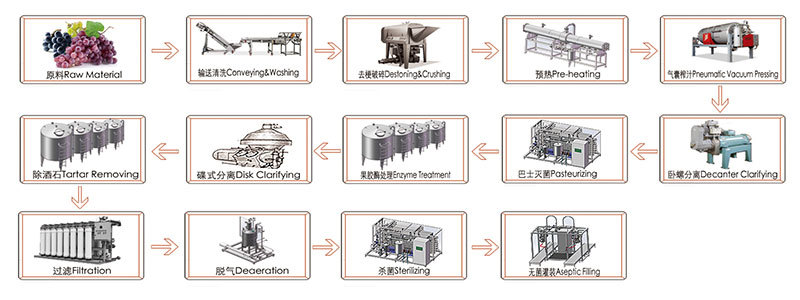

CAD Design

Fine processing

Professional team

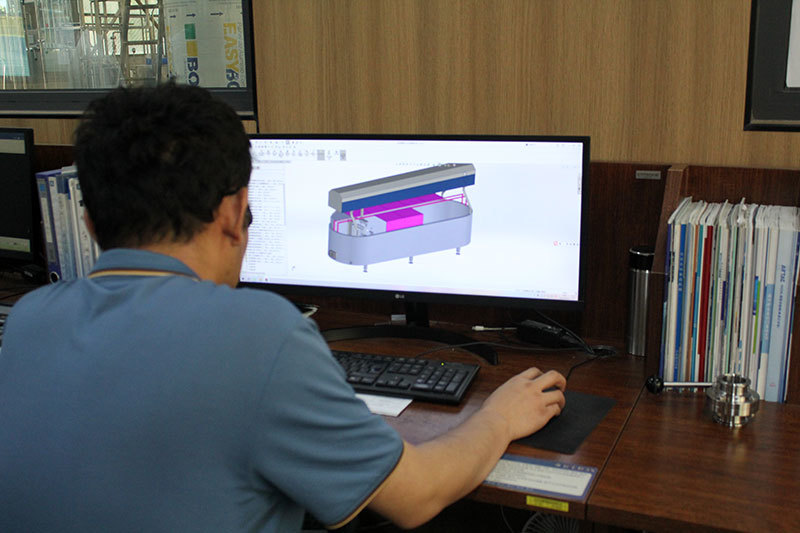

Customer Visit

Packing and shipping

Qualification & Honor

Since its establishment, Shandong Vodasco has received unanimous praise from customers and the industry with its professional products, high-quality services, and good reputation. It has been successfully selected as a "Group Member Unit of China Dairy Association", "Director Unit of Shandong Dairy Association", "Vice Chairman Unit of Shandong Dairy Association Milk Bar Branch", and "Excellent Supplier of China Dairy Bar Industry".

Qualification & Honor

Since its establishment, Shandong Vodasco has received unanimous praise from customers and the industry with its professional products, high-quality services, and good reputation. It has been successfully selected as a "Group Member Unit of China Dairy Association", "Director Unit of Shandong Dairy Association", "Vice Chairman Unit of Shandong Dairy Association Milk Bar Branch", and "Excellent Supplier of China Dairy Bar Industry".

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!