Share to

Milk powder production line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- DESCRIPTION

-

The milk powder processing production line is an equipment that converts liquid milk into high-quality milk powder. The entire production process is strictly controlled to ensure the preservation of the product's flavor and nutrients. Adjust the fat content of milk through a direct standardization system and concentrate the milk to a dry matter content of 35-55% using a falling film evaporator. Then, the excess water in the milk powder is removed through the pressure spray dryer and cooled to ensure that the particle size of the milk powder is uniform, the solubility is good and the wettability is strong.

The advantages of this production line include efficient energy management, full process automation control, and precise production parameter control. The system can accurately control the moisture content, particle structure, solubility, dispersibility, and flavor retention of milk powder. The equipment uses high-quality components and has an effective CIP cleaning system to ensure hygiene and efficiency in the production process.

In addition, the whole milk powder production line supports personalized design and can produce different types of milk powder products according to customer needs, meeting various market demands and having the advantages of high production volume and low loss.

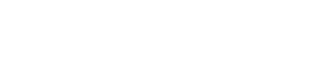

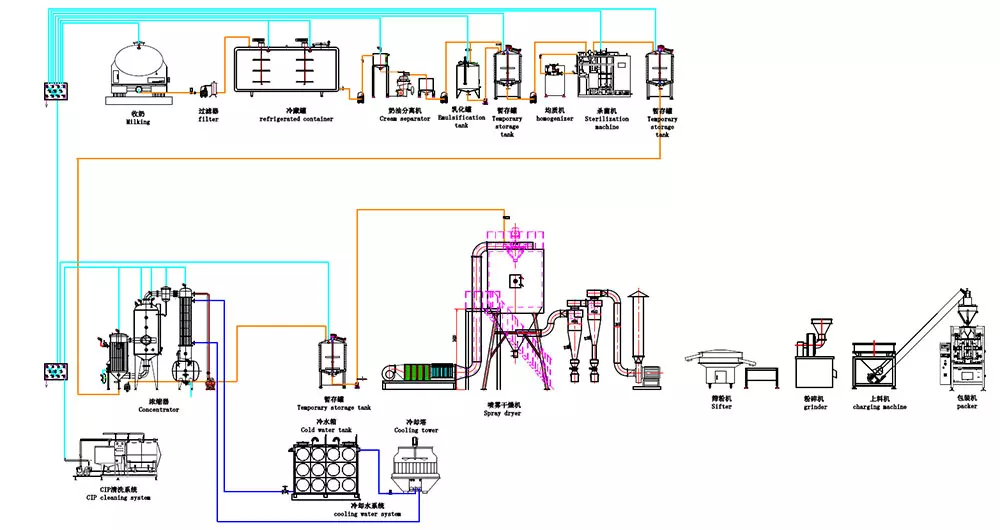

Dry process flow

Wet process flow

Product variety

Skimmed milk powder, whole milk powder, sweet milk powder, infant milk powder, various formula milk powders

Production process flowchart of skimmed milk powder

Production process flowchart of whole milk powder

Advantages of production line

1. It can control the moisture content of milk powder, the required particle structure, uniform particle size, solubility, dispersibility, and moisture retention, as well as the retention of nutrients, aroma, and flavor

2. Optimal ratio of operation and consumption: efficient energy consumption measures; Continuous and rapid evaporation, drying, and cooling; Convenient operation; Effective full process automation control

3. According to user requirements, personalized design with multiple uses ensures the realization of user demands

4. Select high-quality and reliable components, effective CIP cleaning effect, so that the equipment can operate reliably and efficiently for a long time

5. Fully automated control and monitoring, capable of ensuring production meets standards and regulatory requirements from start to finish

6. Different final products can be produced on the same production line

7. Can obtain a wide range of product varieties that meet the needs of users

8. High output, low lossProduct Display

Milk powder production line

Still deciding? Get samples first, Contact US !

Tag list

Complete set of technical solutions

and service providers for the fluid industry

Precision welding

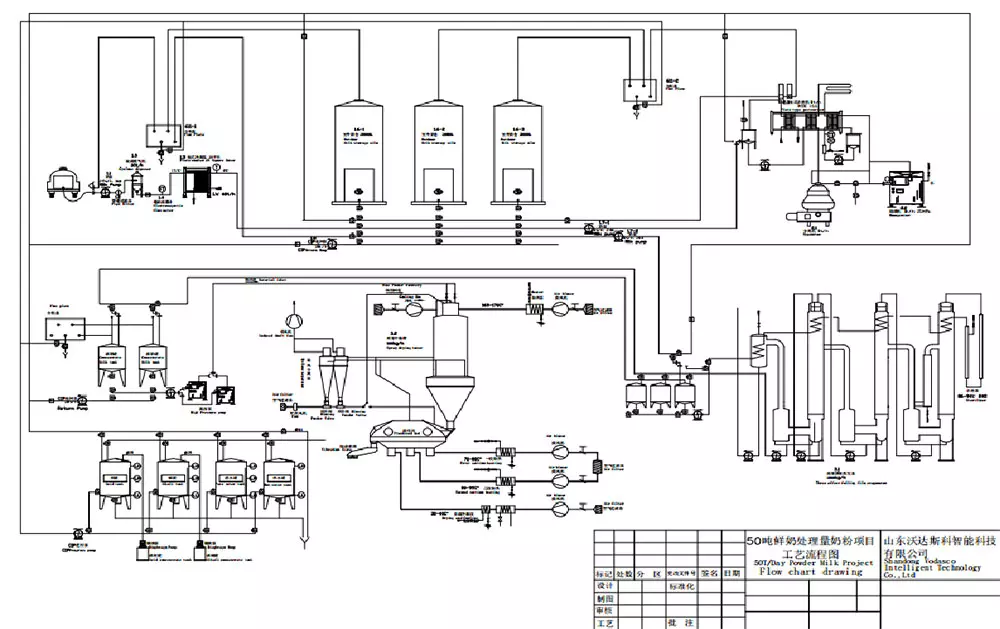

CAD Design

Fine processing

Professional team

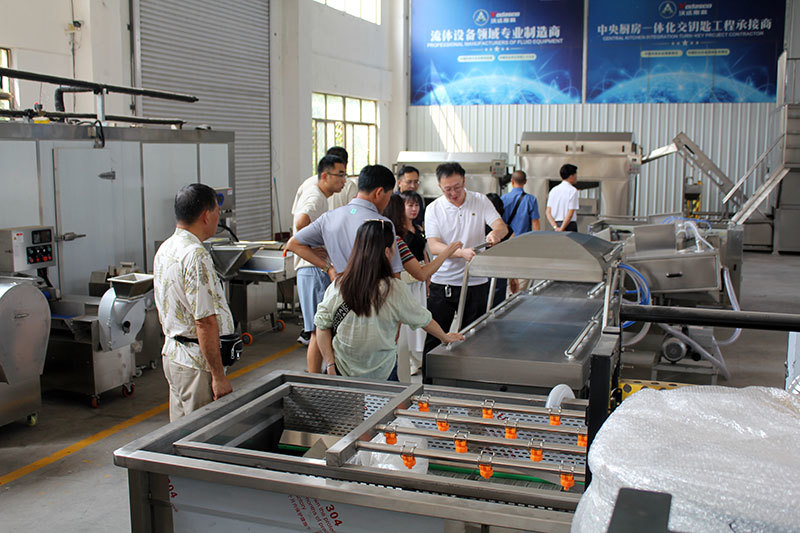

Customer Visit

Packing and shipping

Qualification & Honor

Since its establishment, Shandong Vodasco has received unanimous praise from customers and the industry with its professional products, high-quality services, and good reputation. It has been successfully selected as a "Group Member Unit of China Dairy Association", "Director Unit of Shandong Dairy Association", "Vice Chairman Unit of Shandong Dairy Association Milk Bar Branch", and "Excellent Supplier of China Dairy Bar Industry".

Qualification & Honor

Since its establishment, Shandong Vodasco has received unanimous praise from customers and the industry with its professional products, high-quality services, and good reputation. It has been successfully selected as a "Group Member Unit of China Dairy Association", "Director Unit of Shandong Dairy Association", "Vice Chairman Unit of Shandong Dairy Association Milk Bar Branch", and "Excellent Supplier of China Dairy Bar Industry".

FAQ

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!